Good Facts For Choosing Automated Packaging Machines

The Best Ways To Pack Your Drinks : Glass Bottles Vs Cans

Enoline Solutions has over 30 years experience in designing and connecting secondary and tertiary packing equipment. We have helped more than 50 beverage entrepreneurs. We can help you design a solution that suits your production space, budget and budget, no matter what format your product comes in.

The Different Beverage Containers

You can store your beer, cider mead, etc. You can keep your cider, your beer and mead in various containers. You'll need to consider many factors before making your decision. Marketing, production and sales expenses could all be important. The space requirements can also be important based on whether you export or ship. Sometimes it's a question of finding the perfect balance between these three elements, which can be difficult for companies. Our mission is to assist you make the right decision and provide the most effective solutions. Prior to the packaging that will be offered to the consumer on the store shelves, beverages and especially beers are often delivered in kegs which have the benefit of having more liquid in an overall smaller volume which makes it possible to store and transport more product. The industry uses two containers when producing final products: the bottle and can. Have a look at the top rated réduire les coûts d'emballage for site examples including encaisseuse automatique montréal, top 4 future packaging trends, recyclable paper packaging, industrial shrink wrap machine, machine d'emballage économique québec, fully automatic robotic palletizing system, palettisation automatique ontario, food and beverage industry, packing machine, paquets mixtes, and more.

Glass Bottle Vs.

Beverages are packaged in glass bottles made of PET or. Glass has an elegant appearance. Glass is also more appealing and natural as well as clean. Glass bottles are usually more appealing than cans, which some people consider "metallic". For a better tasting experience it is recommended to serve your drink in glasses. However, today most beverage creators are switching to can packaging due to a variety of reasons: Conservation first foremost, as the can is hermetic and opaque, unlike the transparent bottle it blocks light to cross as well as air by closing that is more secure than a regular screwed cap. Glass bottles are able to permit refermentation and the ageing of your products when needed. It is easier to preserve the freshness of hops inside cans. Cans are able to be stored vertically and can be stacked to save storage space. The style, the design possibilities are limitless on cans, which enables you to distinguish yourself from competitors and to attract the consumer from a marketing point perspective. A can made from steel or aluminum by Ecology is 100% recyclable. They consume less energy to wash than glass bottles that can be 30 times more time-consuming. Cans can be recycled quickly and at a cheaper cost, with a minimum of 60 days. The cans take approximately 280x longer to get fresh than glass bottles. Be careful if are driven by environmental concerns. Don't attach plastic caps to cans. They could contaminate our oceans, and could cause an environmental catastrophe. Choose recyclable cardboard packaging. Our SL-20 is a machine that lets you make all types of packs including the variety of packaging options that customers are raving about. Did you choose the right container? Now is the time to finish the filling, packing, and palletization process prior to distribution. It is possible to automate large amounts by finding a way to automatize them. See the best achat machine emballeuse for website examples including encaisseuse automatique ontario, refroidissement automatique québec, shrink wrap packaging machine, sustainable packaging solutions, specific requirements packaging machine, cans over bottles, beer can size chart, familiar beers, encaisseuse automatique, équipement d’encaissage brasserie, and more.

Automate Your Beverage Packaging

Hygiene

Hygiene is the first reason to use an automated system for packaging. Tools that are not properly used can result in contamination. It's not a problem for health: any agent outside could make beer lose its original flavor and quality. However, the primary concern is safety: just like other equipment for beer the in-house packaging system can make your beer contaminated with chemicals that pose a risk for your health.

Convenience

If you're looking for outside beer packaging suppliers, it is important to find one that is convenient. Did you know that beer is often transported from your brewery to the supplier by truck? Even if you only produce small amounts, it can be quite difficult to manage. If the production rate is high enough to justify selling outside of your brewery, you should look into purchasing automated beer packaging equipment.

Control

Control is an essential aspect of all beer equipment. Packaging equipment is no exception. Professional machines allow you to oversee every step of the process, from cleaning to filling and sealing. Control is vital for your business to be successful. You are also guaranteed the same high-quality product that manual work provides. This is crucial from a customer's perspective. See the top

what does a palletizer do for blog advice including chargement automatisé emballage, top 4 future packaging trends, purchasing your packaging line, automated machines, best packaging machine company, systèmes d’emballage automatique, emballeuse bière, case packings, achat machine emballeuse, bière artisanale non alcoolisée, and more.

Brand

You have a lot of customization options with your professionally-designed automated packaging system. It allows you to design packaging for your favourite beverage and then sell cans or bottles bearing your branding. Marketing is all about branding. It can help ensure that your brand is well-known and popular. Stand out from your competitors! You can also alter the format quickly and easily, as well as the kinds of packs, for example.

Production speed

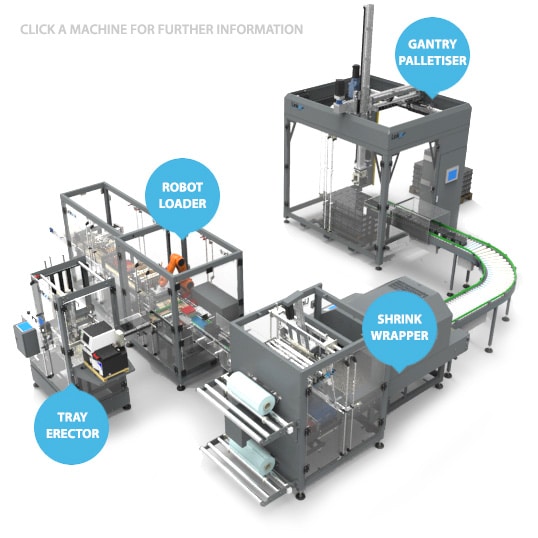

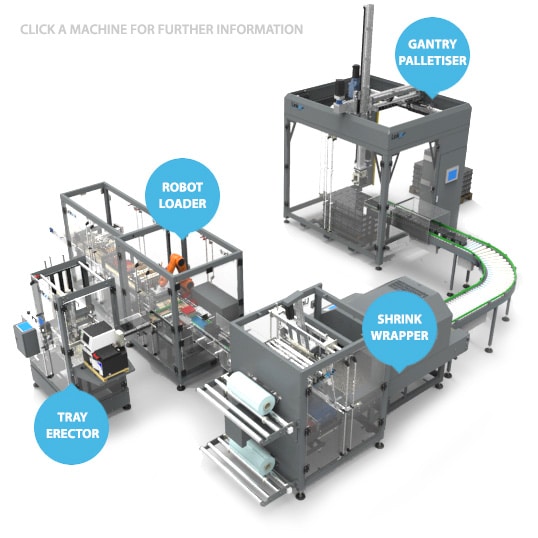

A professional automated packaging system's greatest asset is the speed at which it operates. It can be integrated into the beer equipment you have to dramatically increase the amount of beer you can produce. You'll produce cans, bottles and more with minimal effort and in short amounts of time. This is how you can get your business moving to the next step. Our main solutions to beverage packaging. Our main solutions for beverage packaging comprise automatic filling machines, final packaging for pallets and wrapping around or side loading machines for packaging... We can't provide a complete list of the equipment we provide and recommend that you contact us for a discussion of your needs. You will find it reliable, affordable, fast, and versatile. Read more- Great Ideas For Choosing Automated Packaging Machines 18d9949 , New Ideas For Picking Automated Packaging Machines and New Hints For Choosing Automated Packaging Machines.

Enoline Solutions has over 30 years experience in designing and connecting secondary and tertiary packing equipment. We have helped more than 50 beverage entrepreneurs. We can help you design a solution that suits your production space, budget and budget, no matter what format your product comes in.

The Different Beverage Containers

You can store your beer, cider mead, etc. You can keep your cider, your beer and mead in various containers. You'll need to consider many factors before making your decision. Marketing, production and sales expenses could all be important. The space requirements can also be important based on whether you export or ship. Sometimes it's a question of finding the perfect balance between these three elements, which can be difficult for companies. Our mission is to assist you make the right decision and provide the most effective solutions. Prior to the packaging that will be offered to the consumer on the store shelves, beverages and especially beers are often delivered in kegs which have the benefit of having more liquid in an overall smaller volume which makes it possible to store and transport more product. The industry uses two containers when producing final products: the bottle and can. Have a look at the top rated réduire les coûts d'emballage for site examples including encaisseuse automatique montréal, top 4 future packaging trends, recyclable paper packaging, industrial shrink wrap machine, machine d'emballage économique québec, fully automatic robotic palletizing system, palettisation automatique ontario, food and beverage industry, packing machine, paquets mixtes, and more.

Glass Bottle Vs.

Beverages are packaged in glass bottles made of PET or. Glass has an elegant appearance. Glass is also more appealing and natural as well as clean. Glass bottles are usually more appealing than cans, which some people consider "metallic". For a better tasting experience it is recommended to serve your drink in glasses. However, today most beverage creators are switching to can packaging due to a variety of reasons: Conservation first foremost, as the can is hermetic and opaque, unlike the transparent bottle it blocks light to cross as well as air by closing that is more secure than a regular screwed cap. Glass bottles are able to permit refermentation and the ageing of your products when needed. It is easier to preserve the freshness of hops inside cans. Cans are able to be stored vertically and can be stacked to save storage space. The style, the design possibilities are limitless on cans, which enables you to distinguish yourself from competitors and to attract the consumer from a marketing point perspective. A can made from steel or aluminum by Ecology is 100% recyclable. They consume less energy to wash than glass bottles that can be 30 times more time-consuming. Cans can be recycled quickly and at a cheaper cost, with a minimum of 60 days. The cans take approximately 280x longer to get fresh than glass bottles. Be careful if are driven by environmental concerns. Don't attach plastic caps to cans. They could contaminate our oceans, and could cause an environmental catastrophe. Choose recyclable cardboard packaging. Our SL-20 is a machine that lets you make all types of packs including the variety of packaging options that customers are raving about. Did you choose the right container? Now is the time to finish the filling, packing, and palletization process prior to distribution. It is possible to automate large amounts by finding a way to automatize them. See the best achat machine emballeuse for website examples including encaisseuse automatique ontario, refroidissement automatique québec, shrink wrap packaging machine, sustainable packaging solutions, specific requirements packaging machine, cans over bottles, beer can size chart, familiar beers, encaisseuse automatique, équipement d’encaissage brasserie, and more.

Automate Your Beverage Packaging

Hygiene

Hygiene is the first reason to use an automated system for packaging. Tools that are not properly used can result in contamination. It's not a problem for health: any agent outside could make beer lose its original flavor and quality. However, the primary concern is safety: just like other equipment for beer the in-house packaging system can make your beer contaminated with chemicals that pose a risk for your health.

Convenience

If you're looking for outside beer packaging suppliers, it is important to find one that is convenient. Did you know that beer is often transported from your brewery to the supplier by truck? Even if you only produce small amounts, it can be quite difficult to manage. If the production rate is high enough to justify selling outside of your brewery, you should look into purchasing automated beer packaging equipment.

Control

Control is an essential aspect of all beer equipment. Packaging equipment is no exception. Professional machines allow you to oversee every step of the process, from cleaning to filling and sealing. Control is vital for your business to be successful. You are also guaranteed the same high-quality product that manual work provides. This is crucial from a customer's perspective. See the top

what does a palletizer do for blog advice including chargement automatisé emballage, top 4 future packaging trends, purchasing your packaging line, automated machines, best packaging machine company, systèmes d’emballage automatique, emballeuse bière, case packings, achat machine emballeuse, bière artisanale non alcoolisée, and more.

Brand

You have a lot of customization options with your professionally-designed automated packaging system. It allows you to design packaging for your favourite beverage and then sell cans or bottles bearing your branding. Marketing is all about branding. It can help ensure that your brand is well-known and popular. Stand out from your competitors! You can also alter the format quickly and easily, as well as the kinds of packs, for example.

Production speed

A professional automated packaging system's greatest asset is the speed at which it operates. It can be integrated into the beer equipment you have to dramatically increase the amount of beer you can produce. You'll produce cans, bottles and more with minimal effort and in short amounts of time. This is how you can get your business moving to the next step. Our main solutions to beverage packaging. Our main solutions for beverage packaging comprise automatic filling machines, final packaging for pallets and wrapping around or side loading machines for packaging... We can't provide a complete list of the equipment we provide and recommend that you contact us for a discussion of your needs. You will find it reliable, affordable, fast, and versatile. Read more- Great Ideas For Choosing Automated Packaging Machines 18d9949 , New Ideas For Picking Automated Packaging Machines and New Hints For Choosing Automated Packaging Machines.